OMISA WhiteLine WeldControl 2.0

The handling of a WeldControl machine is simply unique and it enables an approach to welding no other system is able to offer. Either the operator makes use of the assistance of the interactively responding hydraulic and control unit. Or the manual mode is selected to make the joint “by hand”.

In the WeldControl mode the system walks the operator through the process after the pipe parameters were entered or confirmed. This includes monitoring the operator’s inputs and recording the entire process. WeldControl machines do not only provide presets, though; they facilitate the work, e. g., by reducing the pressure automatically when the automode was enabled. Welding reports have all data required by ISO traceability.

In the Manual mode the display screen works as a digital gauge. It displays the welding pressures and heating element temperatures and is a one-stop provider of all data.

Automatic data logging

10,000 welding operations

Data input

WeldControl mode:

RFID transponder, scanner or manually

Manual mode:

Manual temperature control

System settings

Automode, manual input of welding parameters, gauge operation (for pressure, temperature)

Welding monitoring system

Welding pressures, welding times, ambient temperature, memory control, operating temperature, heating element temperature

Standard-compliant ISO 12176 traceability

Commission number with 32 alphanumeric characters, ISO-compliant welder ID code, OMISA welder ID code, 1st additional (user-defined) data with 20 alphanumeric characters 2nd additional (user-defined) data with 15 alphanumeric characters, ISO-compliant traceability: fitting code, 1st and 2nd pipe codes, pipe length, weather conditions, joint number, installing company, inventory number

Welding standard

DVS, WIS, SEDIGAS, UNI, and others upon request

Data output

USB port for data transfer as short abstract or extended report in the PDF format to a USB stick or a label tag printer, incl. tag printer menu; transfer also possible in the OMISA DataWork format, with powerful download menu with date range selection, commission number selection, and download of all reports in memory

Miscellaneous

Easy switch from WeldControl mode to Manual mode by a dedicated keypress; ViewWeld: viewing reports on the display rather than printed

Hydraulic and control unit

Only one external power supply needed—power to all electronic components is supplied from the hydraulic unit; automatic heating element temperature control pursuant to national standards; hydraulic unit in encased, rugged steel enclosure with a weight of as little as 19.5 kg (up to O.D. 355 mm); max. pressure, up to O.D. 355 mm, 130 bar; O.D. 500 - 630 mm, 150 bar; O.D. 800 - 1600 mm, 220 bar

Languages

DE, EN, FR, BG, CS, ZH, NL, FI, GR, IT, NO, RO, SK, TR, RU, and others upon request

Technical Specs

| Dimension | 160 mm | 250 mm | 315 mm | 355 mm | 500 mm | 630 mm | 800 mm | 1000 mm | 1200 mm | 1400 mm | 1600 mm |

| P/N SP-CW... | .160 | .250 | .315 | .355 | .500 | .630 | .800 | .1000 | .1200 | .1400 | .1600 |

| Operating range, O.D. | 40 - 160 mm | (63) 75 - 250 mm | 90 - 315 mm | 90 - 355 mm | (200) 250 - 500 mm | 315 - 630 mm | 500 - 800 mm | (630) 710 - 1000 mm | (630) 710 - 1200 mm | 800 - 1400 mm | 800 - 1600 mm |

| Power supply | 230 V | 230 V | 230 V | 230 V | 400 V | 400 V | 400 V | 400 V | 400 V | 400 V | 400 V |

| Frequency | 50 Hz | 50 Hz | 50 Hz | 50 Hz | 50 Hz, 3 ph. | 50 Hz, 3 ph. | 50 Hz, 3 ph. | 50 Hz, 3 ph. | 50 Hz, 3 ph. | 50 Hz, 3 ph. | 50 Hz, 3 ph. |

| Rated power | 2.45 kW | 3.65 kW | 4.65 kW | 5.25 kW | 6.45 kW | 11.65 kW | 16.8 kW | 21.2 kW | 23 kW | 43,5 kW | 54 kW |

| Overall weight incl. all components | 66 kg | 109 kg | 168 kg | 201 kg | 295 kg | 448 kg | 771 kg | 1135 kg | 1998 kg | 2100 kg | 2450 kg |

| Reducer inserts | 40 - 140 | (63), 75 - 225 | 90 - 280 | 90 - 315 | (200, 225) 250 - 450 | (250, 280) 315 - 560 | (400, 450) 500 - 710 | (630) 710 - 900 | (630) 710 - 1000 | 800 - 1200 | 1000 - 1400 |

Literature

Brochures

|

User's Manuals

| OMISA WhiteLine WeldControl 2.0 160 | IT | EN | ES | DE | FR | 3.3 MB | |

| OMISA WhiteLine WeldControl 2.0 250 | IT | EN | ES | DE | FR | 3.5 MB | |

| OMISA WhiteLine WeldControl 2.0 315 | IT | EN | ES | DE | FR | 3.4 MB | |

| OMISA WhiteLine WeldControl 2.0 500 | IT | EN | ES | DE | FR | 3.4 MB | |

| OMISA WhiteLine WeldControl 2.0 630 | IT | EN | ES | DE | FR | 3.4 MB |

Components

Welding neck support

Welding neck support

| 160P.OR O.D. 160, 40 - 160 mm | 200P.OR O.D. 200, 63 - 200 mm | 250P.OR O.D. 250, 63 - 250 mm | 315P.OR O.D. 315, 90 - 315 mm |

| 355P.OR O.D. 355, 90 - 355 mm | 500P.OR O.D. 500, 200 - 500 mm | 630P.OR O.D. 630, 315 - 630 mm | 800P.OR O.D. 800, 500 - 800 mm |

| 1000P.OR O.D. 1000, 710 - 1000 mm | 1200P.OR O.D. 1200, 710 - 1200 mm | 1400P.OR O.D. 1400, 800 - 1400 mm | 1600P.OR O.D. 1600, 1000 - 1600 mm |

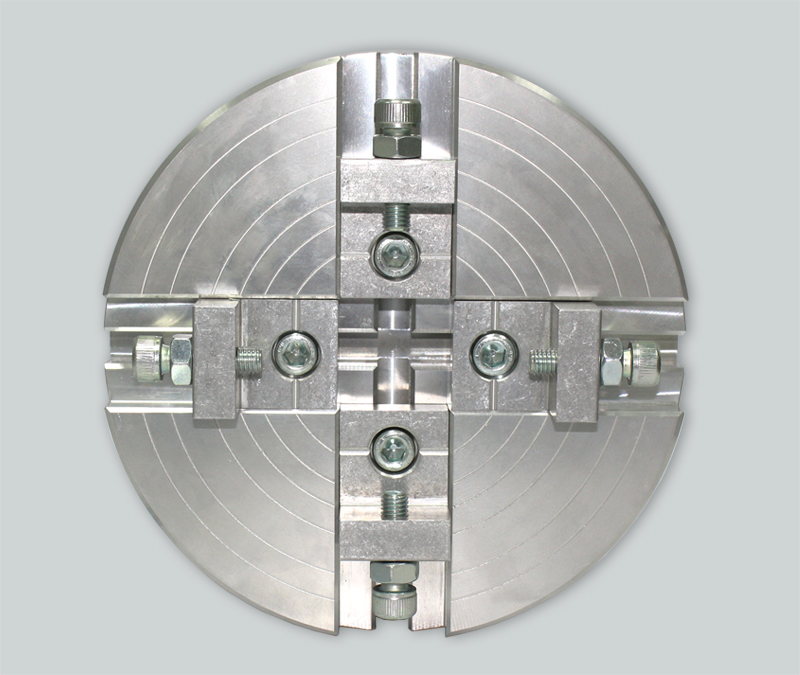

Set of aluminum reducers

Set of aluminum reducers

| RID.160PS 160 (D 40 - 140) | RID.250V1 250 (D 75 - 225) | RID.315PS 315 (D 90 - 280) | RID.355PS 355 (D 90 - 315) |

| RID.500PP 500 (D 250 - 450) | RID.630PP 630 (D 315 - 560) | RID.800PP 800 (D 500 - 710) | RID.1000PP 1000 (D 710 – 900) |

| RID.1200PP 1200 (D 710 – 1000) | RID.1400PP 1400 (D 800 – 1200) | On request 1600 (D 1000 – 1600) |

Set of steel reducers

Set of steel reducers

| R.STL160 160 (D 40 - 140) | R.STL250 250 (D 75 - 225) | R.STL315 315 (D 90 - 280) | R.STL355 355 (D 90 - 315) |

ISO welder ID code

ISO welder ID code

| RFID code card 217-010-061 |